【SAL series】 The purpose, usage method, and application scenarios of a six degree of freedom flexibl

The spatial six degree of freedom flexible adapter is particularly suitable for situations where there are errors in the spatial position and spatial angle posture of objects grasped or implanted by six axis robots.The SAL series flexible adapter is particularly skilled in automatically compensating or correcting spatial position errors, angle errors, posture errors, and repetitive positioning errors of the working object after being grasped, transported, and implanted in the injection molding production line (repair) of automotive electronic connectors with precision embedded parts injection molding. It significantly reduces the robot's precise position and posture teaching time by more than 95%.

【 Instructions 】:

a. Install this flexible adapter on the wrist of an automatic handling mechanism or a six axis robot, and install a product handling fixture underneath it;

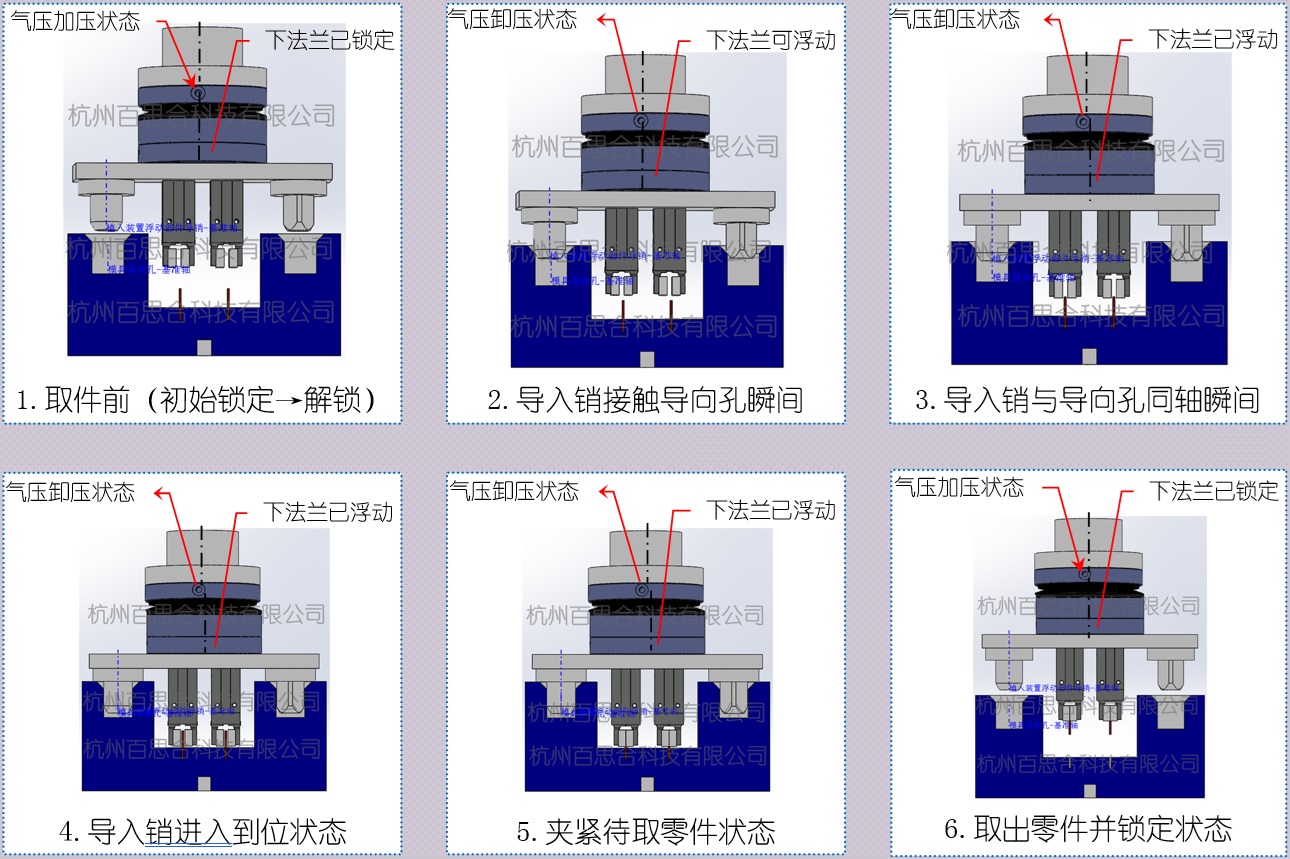

b. The automatic handling mechanism or six axis robot approaches the target area, removes air pressure, unlocks the adapter, and flexibly adapts to grasp the target part;

c. The automatic handling mechanism or six axis robot takes out the parts from its positioning fixture, and then the air pressure drives the locking flexible adapter again;

d. Automatic handling mechanism or six axis robot moves to the target area (inside the mold) for placing (to be implanted) parts (inserts);

e. Remove the air pressure, unlock the adapter, flexibly fit the spatial position and posture deviation between the part (insert) and the target (mold), and the automatic handling mechanism or six axis robot smoothly places (implants) the part (insert) into the target (mold);

f. After the automatic handling mechanism or six axis robot disengages from the target (mold), the flexible adapter is locked by pneumatic drive;

g. The automatic handling mechanism or six axis robot moves to the starting position of the next cycle of work;

h. Repeat the steps b~g in a loop.

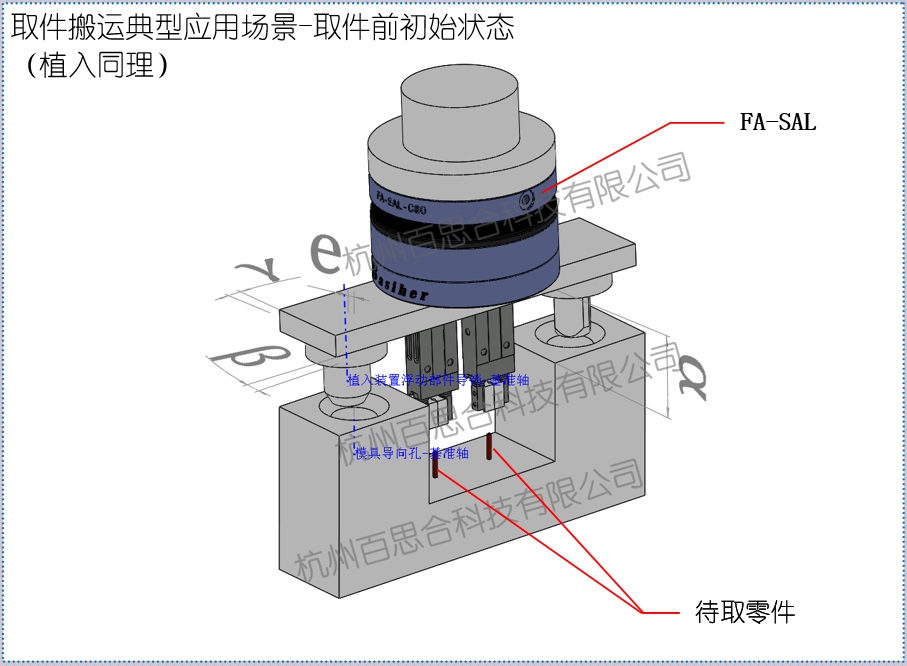

Application scenario diagram for handling and picking up items: