【QIC series】 Use, Instructions, and Application Scenarios of Intelligent Internal Surface Occluders

2024-06-07 13:48 BosFun

Intelligent surface sealing devices are used for products that require rapid sealing (or leak testing, sealing testing, waterproof testing) in situations where there are light holes or threaded holes on the inner surface.The QIC series occluder of brand Basiher can automatically compensate or correct the positioning accuracy and repeated positioning errors of the tested product, thereby eliminating the adverse effects of positioning accuracy errors on the stability of occlusion detection.

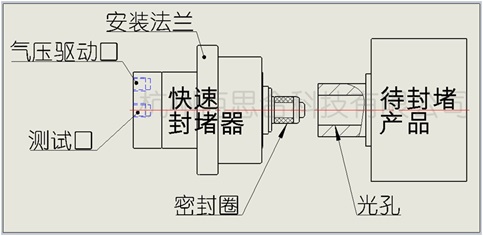

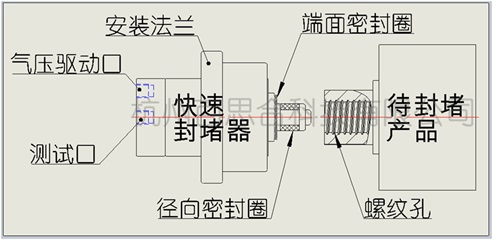

a. Install and fix the flange of this occluder on the test bench support, and clamp the occluded product in its positioning fixture;

b. The head of the occluder enters the inner hole of the product to be occluded;

c. Inject compressed air into the pneumatic drive port, the sealing ring expands and adapts to be coaxial with the inner hole of the product, and completes stable and reliable sealing of the inner hole of the product;

d. Inject test pressure gas into the testing port to test the product (typical processes include inflation, stabilization, testing, and exhaust);

e. After the test is completed, the air pressure drives the exhaust port, the sealing ring shrinks, and the head of the occluder leaves the inner hole of the product.

1.Scene diagram for sealing optical hole products:

2.Scenediagram for sealing threaded hole products:

声明:此篇为百思合的网站原创文章,转载请标明出处链接: http://basiher.com/en/h-nd-5.html